Acoustic Imager Casing Evaluation Tool

Precision Casing and Borehole Inspection

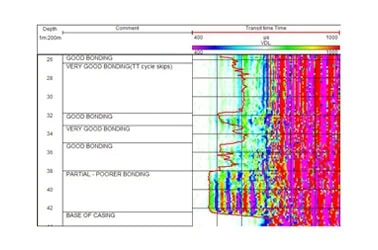

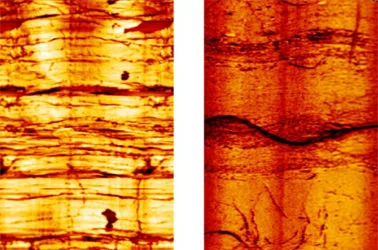

The Acoustic Imager Casing Evaluation Tool is designed to provide high-resolution images of borehole walls or casing interiors. Using a rotating ultrasonic sensor, the tool measures the travel time and amplitude of reflected acoustic signals. This data is used to assess casing integrity and identify potential issues with exceptional accuracy.

The amplitude of the reflected signal provides insight into the elastic properties of the casing, while the travel time delivers precise borehole diameter measurements. These capabilities make the tool ideal for detailed casing inspections to detect:

- Inner Corrosion

- Outer Corrosion

- Wall/Casing Thickness Variations

- Internal Deposits or Encrustations

- Pipe Deformities or Buckling

Key Features

Specifications

- Dimensions: 1160mm (length) x 60mm (diameter)

- Weight: 6kg

- Tilt Range: 0°–90°

- Azimuth Range: 0°–360°

- Vertical Resolution: User-defined, up to 0.5mm

- Horizontal Resolution: User-defined, up to 360 measurements/revolution

- Rotation Speed: Up to 35 revolutions per second

- Caliper Resolution: 0.08mm

- Maximum Temperature: 70°C

Logging Conditions

- Logging Speed: 0.5–2 m/min

- Centralised operation required

Borehole Compatibility

- Minimum Diameter: 76mm

- Maximum Diameter: 500mm

The Acoustic Imager Casing Evaluation Tool is the ultimate solution for detailed casing and borehole inspections. Its advanced ultrasonic technology ensures accurate data acquisition, making it an invaluable tool for maintaining borehole and casing integrity in geotechnical, hydrogeological, and industrial applications.